No problem, SADE has got the skills!

As part of a judicial enquiry led by OFB (the French Biodiversity Office or “environmental police”), DREAL (Direction Régionale de l’Environnement, de l’Aménagement et du Logement, i.e. Regional Environment, Development & Housing Directorate) issued formal notice to Gelagri, a Loudéac-based business, regarding its wastewater discharge management.

Excerpt from Ouest France newspaper

“Kilometres of stream have been polluted”, says Alain Marteil, chairman of Loudéac fishery (Côtes-d’Armor). “This is organic pollution spreading down from the Calouët stormwater basin that appears to have been discharged into the Ouest River level near La Ville Léo”, explains Jean Leveaux, deputy chairman of Loudéac fishery.

The client’s hydraulic infrastructure

Every year, mainly to wash the vegetables it processes, Gelagri uses nearly 600,000m3 of water, which is then discharged towards the municipal wastewater treatment plant.

Gelagri has a pre-treatment facility and a 6,000m3 lagoon to store its pre-treated water. This lagoon, which is a banked, open-air balancing tank with a waterproof geomembrane (80 x 40 x 3), is used to smooth discharge peaks and ensure a constant discharge rate by smoothing peaks.

And this is what attracted the authorities’ attention…

The client’s issue

The tank is not waterproof. Its membrane is torn in several places, which causes wastewater infiltration. The under-surface water drainage system is inoperative. The tank is unstable and its slopes no longer hold in place. The absence of gas exhaust vents increases its instability. A risk of subsidence cannot be ruled out.

The tank serves as a settling tank. Washing vegetables produces a large amount of earth and sand. Organic sludge is found at the bottom of the tank and on the walls. To extract it, the operator uses crane-driven machines to scrape the membrane, plus manual pumping and extraction. This approximative and labour-intensive process results in irregular sludge extraction.

SADE’s solution

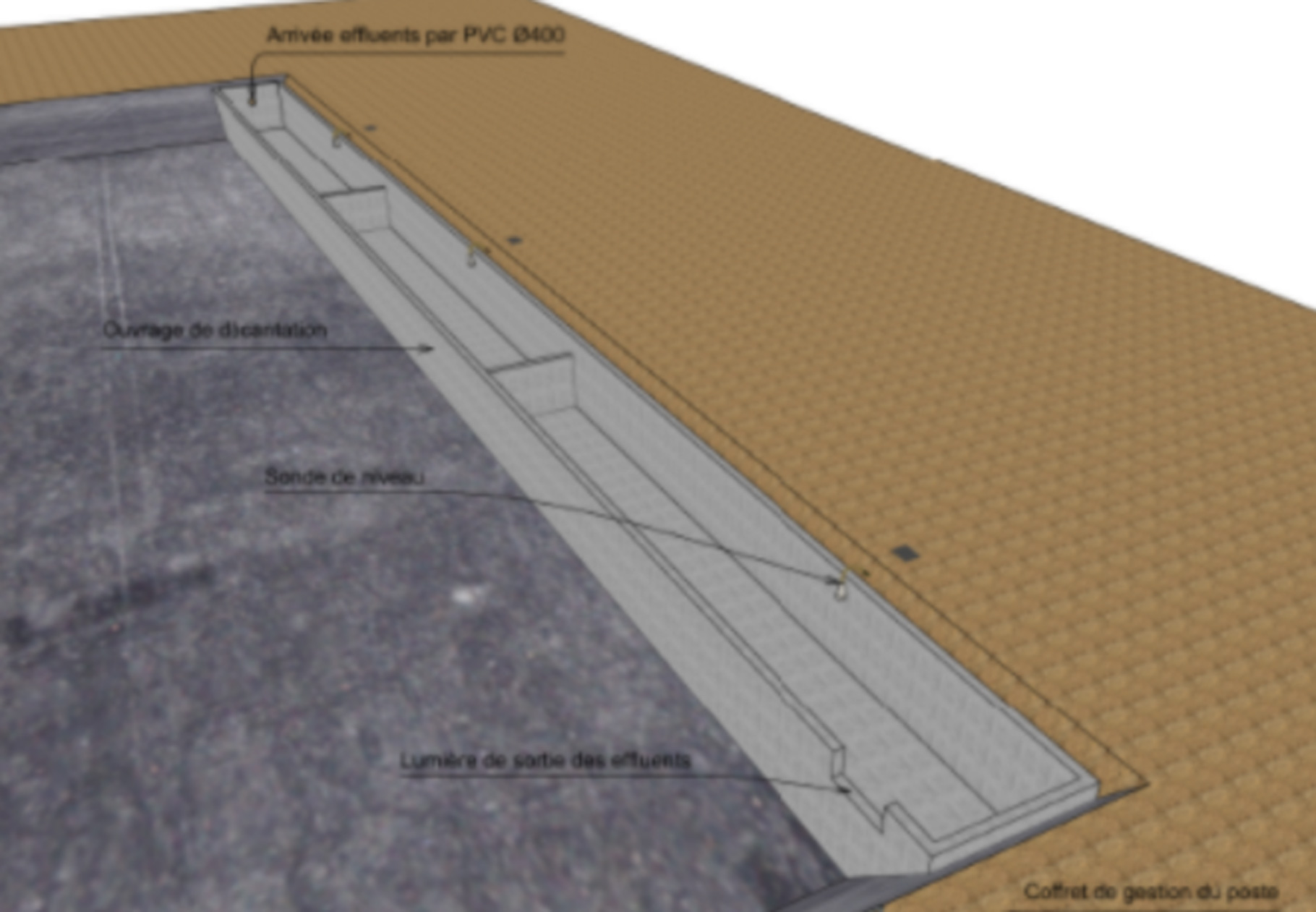

Designed by SADE Engineering, the new plan immediately won over the client. The aim is to renovate the lagoon, adding a specific decanting channel.

- The structure is designed and built using prefabricated walls to speed up the construction process.

- The incoming flows have been reorganised to route effluent via a specifically-sized concrete channel (77m long, 4m wide and 3m high) to provide both effective decanting and high-volume storage.

- This compartmented structure maintains continuous service: not only is effluent treated but both sludge extraction and discharge are maintained.

- This channel is equipped with stench traps and also features sludge level sensors.